What is high purity quartz sand for sale?

Sinonine high purity quartz sand production line is used to produce high purity and ultra-high purity quartz sand with SiO2 content higher than 99.999% for the production of quartz crucible and high-end electronics industry. Selecting the appropriate quartz stone as the raw material and processed in the high purity sand production line, through a series of purification processes the high purity quartz sand is obtained, an annual output of 3000-50,000 tons of large-scale industrial production capacity can be achieved. Sinonine owns the state-of-art technology in HPQ purification at the world's leading level.

What are the applications of High purity quartz sand(HPQ)plant?

The high-purity quartz sand production line is used to produce high-purity quartz sand and ultra high purity quartz sand, with a SiO2 content of up to 99.999%, meeting the needs of high-end manufacturing industries, mainly reflected in the following aspects.

-Quartz crucible sand

-Quartz tube sand

-Quartz ingot sand

-Electronic sand

-Quartz glass

|  |

|  |

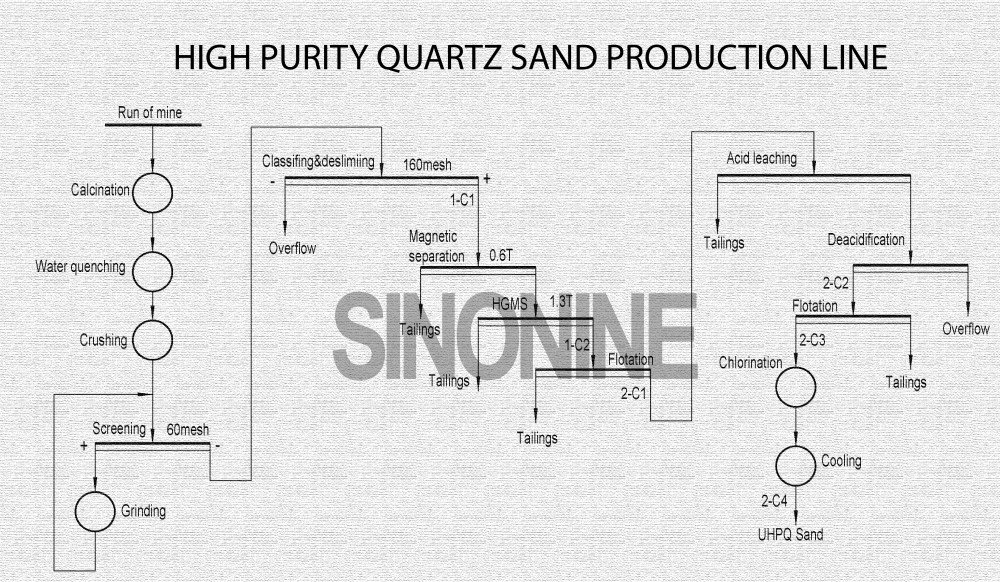

High purity quartz technical process

After the quartz ore is necessarily prepared, the high purity quartz sand production line is employed with the advanced production process, according to the process flow: calcination - water quenching - crushing - grinding - screening - classifying&desliming - magnetic separation - flotation - acid leaching - flotation - high temperature chlorination and other processes for detailed treatment, and SiO2 content of more than 99.999% of high purity quartz sand is obtained. The detailed process flow of the high purity quartz sand production line is as follows: the raw ore is prepared to be about 20mm, and it is calcined in the quartz sand water quenching furnace, and then water quenching, and the raw materials after water quenching are dried for next process. The quartz lump after water quenching enters the rod mill for grinding, screening out -60 mesh quartz sand for desliming and classifying, removing -160 mesh quartz sand, and obtaining first concentrate 1-C1 with particle size of 60-160mesh. Then the first concentrate 1-C1 is put into the high gradient magnetic separator for magnetic separation. After going through two stages magnetic separation with magnetic field strength 0.6T and1.3T the magnetic separation concentrate 1-C2 is obtained. Sent magnetic separation concentrate 1-C2 into the flotation machine, adjusting the PH value of slurry, stirring and adding flotation agents, then the flotation concentrate 2-C1 is obtained through flotation process. Flotation concentrate 2-C1 is then sent to acid leaching reactor, and acid solution is added, and constant temperature acid leaching is carried out. After acid leaching, the concentrate 2-C2 is washed by scrubbing machine to remove acid from quartz sand to obtain concentrate 2-C2. The 2-C2 concentrate is then put into the flotation machine for flotation to obtain concentrate 2-C3. The flotation concentrate 2-C3 is then put into the calcining furnace, chlorinated by HCL gas at high temperature, and then cooled to obtain the final high-purity quartz sand concentrate 2-C4. The detailed flow chart is as follows.

High purity quartz sand calcination and water quenching

The prepared quartz raw ore is calcined at high temperature in the water quenching furnace. After calcination, it is directly put into cold water for water quenching. After water quenching, the quartz ore is cracked inside, so that it is easy to crush and grind.

|  |

High purity quartz sand grinding and classifying

The quartz stone ore after water quenching should be put into the rod mill/ball mill for grinding, and then enter the hydraulic classifier for classifying, to obtain quartz sand particles in the size range of 60-180mesh, and the particle size of quartz sand is ready for the purification process.

High purity quartz sand magnetic separation

The quartz sand goes through the high gradient magnetic separator to remove the magnetic minerals in the quartz sand, generally 2-3 stages magnetic separation system is deployed, adjusting the magnetic field intensity at different stage, and gradually remove the strong magnetic minerals and weak magnetic minerals in the quartz sand to minimize the iron content.

|  |

High purity quartz sand flotation

The flotation of high purity quartz sand is completed in the special flotation machine for high purity quartz sand, the PH value of high purity quartz sand slurry is adjusted, the special flotation reagent for high purity quartz sand is added, and the impurity components in the quartz sand are removed by one or multiple stages of flotation. Flotation is a key step in purifying and removing impurities of high purity quartz sand, which directly affects the quality and grade of high purity quartz sand.

High purity quartz sand acid leaching

High purity quartz sand acid leaching should be carried out in the high purity quartz sand acid leaching reactor, the vulcanized reactor can resist high temperature and corrosion, the quartz sand is put into the reactor, adding oxalic acid, hydrochloric acid, hydrofluoric acid and other acid solutions, stirring at constant temperature for several hours, completely remove the residual impurities inside the quartz sand.

|  |

High temperature chlorination of high purity quartz sand

High temperature chlorination of high purity quartz sand is carried out in the chlorination calcination furnace, which is used to remove the gas-liquid inclusions and hydroxyl impurities inside the quartz sand. After chlorination, the purity of the quartz sand is as high as 99.999%. After cooling and packaging, it will be the final high purity quartz sand product.

|  |

Harmful impurities of high purity quartz sand

The harmful impurities in high purity quartz sand must be strictly controlled , regular test and inspection of the impurities index should be done, the 12 impurities of high purity quartz sand are Ni,Fe,Mn, Cr, Mg, Ca, Cu, Ti, Al, Na, Li.

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087