What is a frac sand washing plant for sale?

Frac sand is a form of proppant for the fracking process used in the oil and gas industry Frac sand particles must be well rounded, high silica content above 99%, and relatively clean of other materials or impurities. Frac sand is processed through a series of technical processes to obtain final product that meets the requirements of oil and gas proppant. Conventional frac sand size includes 20-40 mesh, 40-70 mesh, 70-140 mesh, etc., meeting the needs of different stages. The raw materials of silica sand are processed by means of impurity removal, attrition scrubbing, classification, dewatering, drying, screening to obtain frac sand products of different specifications.

Requirements for frac sand can include

- Silica content of 99% or higher.

-Size fractions typically 20-40 mesh, 40 -70mesh or 70-140mesh.

-Sphericity and roundness of greater than or equal to 0.6.

-Low acid solubility.

-High crush resistance - can withstand compressive stresses of 4,000 to 6,000 psi.

-Turbidity less than 250NTU.

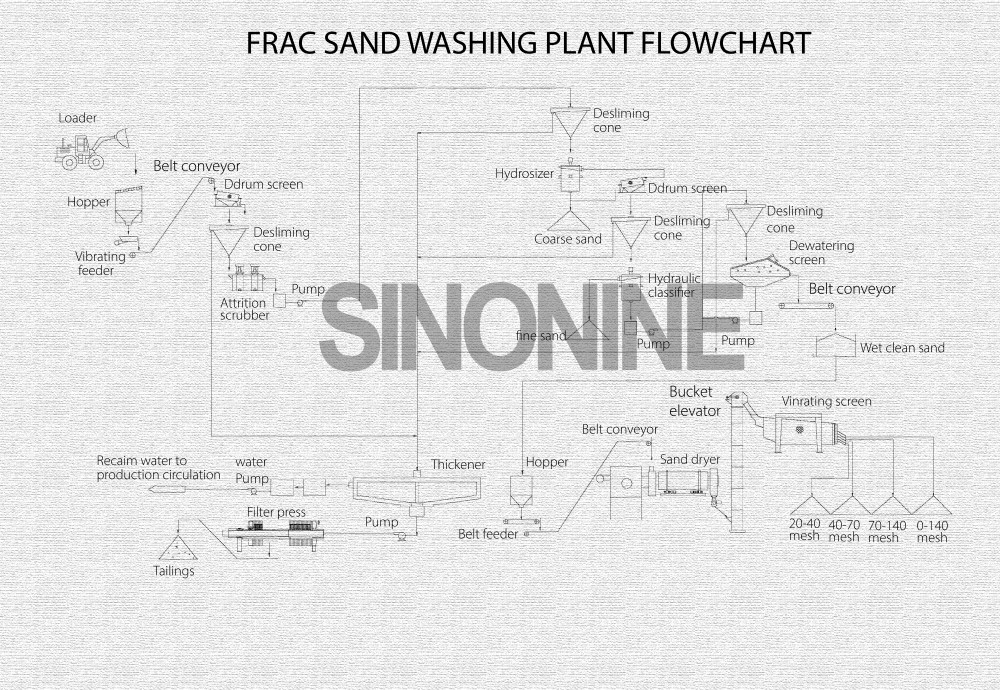

The technical process of frac sand washing plant

By forcing attrition scrubber to remove the impurities wrapped on the surface of the silica sand, then by sand washing machine to remove impurities, the pure silica sand shall be classified by hydraulic classifier and hindered settling machine to obtain frac sand products suitable for requirements of different particle size range, finally after dewatering process the qualified dty frac sand products shall be obtained.

Features of frac sand washing plant

1. The production line has strong applicability and can be applied to all kinds of silica sand;

2. Use strong scrubbing process to remove impurities;

3. The production line has high efficiency and can be automatic controlled;

4. Strict particle size control and automatic adjustment;

5. The product has uniform size and intact shape without damage.

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087