For the soil and impurities in silica sand, it is necessary to conduct a thorough washing process to remove all the organic matters and other impurities that affect the quality of silica sand. Sinonine has developed various sand washing processes for different targeted industries. It adopts wheel sand washer, spiral sand washing machine and other high-efficiency sand washing machines to fully remove impurities from silica sand. For sand with high content of impurities, it adopts multi-stage washing operation. For the sand that is difficult to be cleaned only with washing, the pretreatment process of scrubbing is arranged to make the washing effective and sufficient for obtaining high pure silica sand.

Features of silica sand washing plant

1. Wide application range of the production line;

2. Make full use of water flow to reduce pollution discharge;

3. The finished product is fully washed and clean;

4. Low energy consumption and low production cost;

5. Simple process layout and convenient operation.

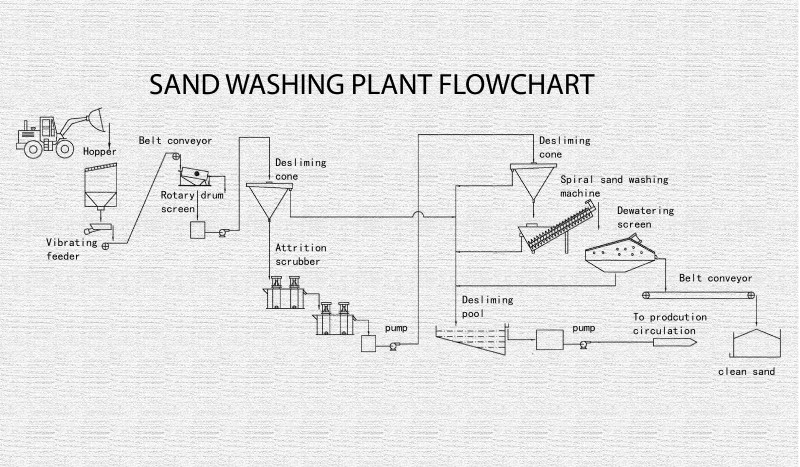

The technical process of silica sand washing plant

Silica sand containing impurities is fed into the sand washing equipment by the feeding equipment. Under the action of water flow, the sand and water are fully mixed. The sand washing machine can fully wash the slurry formed by the sand and water. Dirt and other impurities are dissolved into the water and discharged out of the equipment, and qualified pure quartz sand is discharged into the finished product area. For the sand that is difficult to be cleaned only with washing, the pretreatment process of scrubbing with attrition scrubber is arranged to remove the impurities wrapped in the surface of sand, and then through the washing equipment to remove impurities, and get pure silica sand products. Silica sand washing system can be used alone, or as an important section of silica sand production line, combined with other processes to complete the whole silica sand production process.

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087