What is a spiral concentrator for sale?

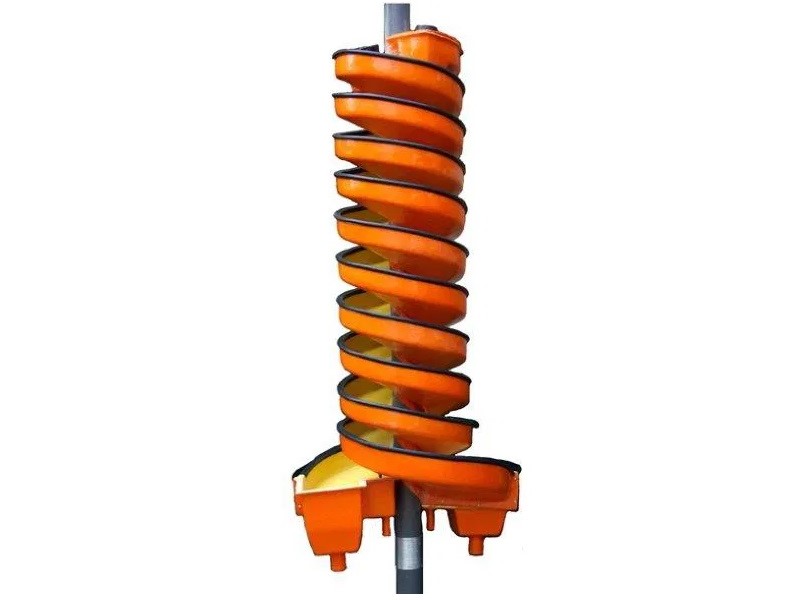

A spiral concentrator named as spiral separator, spiral chute is a device that relies on gravity to separate material in a slurry feed. The light density granules are separated from the heavier density material. Sinonine spiral concentrators are used across the world in silica sand,gold, iron ore, mineral sands, platinum, coal and chrome processing plants as part of the beneficiation process and separates ore and material between 40 and 2000 microns.

Work principle of spiral concentrator

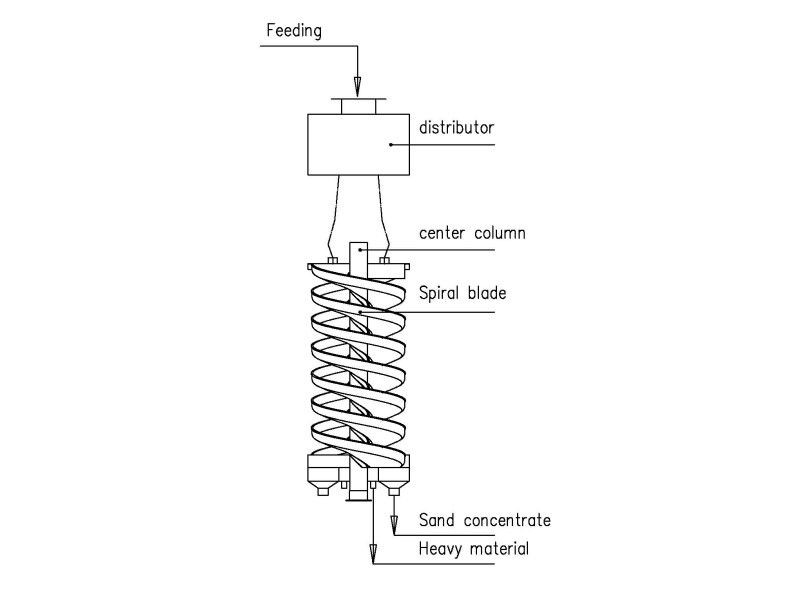

During separation in sand washing plant, the slurry enters the spiral concentrator through a feed box and then flows on to the spiral surface. As the slurry flow downward the spiral, mineral grains settle and sort according to size, shape, and specific gravity.

Spiral separation uses a flowing film principle based on the size and specific gravity difference present in a mineral suite. When fed a dilute pulp mixture of minerals of different specific gravities, the lighter minerals are more readily suspended by the water and attain relatively high tangential velocities so that they climb toward the outer rim of the spiral trough. At the same time, the heavier, non-suspended grains migrate by saltation along the spiral surface at the lowest portion of the spiral cross section. In a spiral concentrator, heavy mineral concentrate is selectively directed into the spiral trough near the inside of the spiral surface through the use of adjustable product splitters. The concentrate then flows through product discharge outlet ports down the length of the helix.

The slurry flows into the static distributor and is evenly distributed in the spiral concentror. Under the action of gravity, the slurry rotates and flows down along the spiral blades. During the descent process, heavy minerals fall along the inner ring of the spiral, while silica sand has a relatively light specific gravity and falls along the outer ring. Finally, heavy minerals are separated.

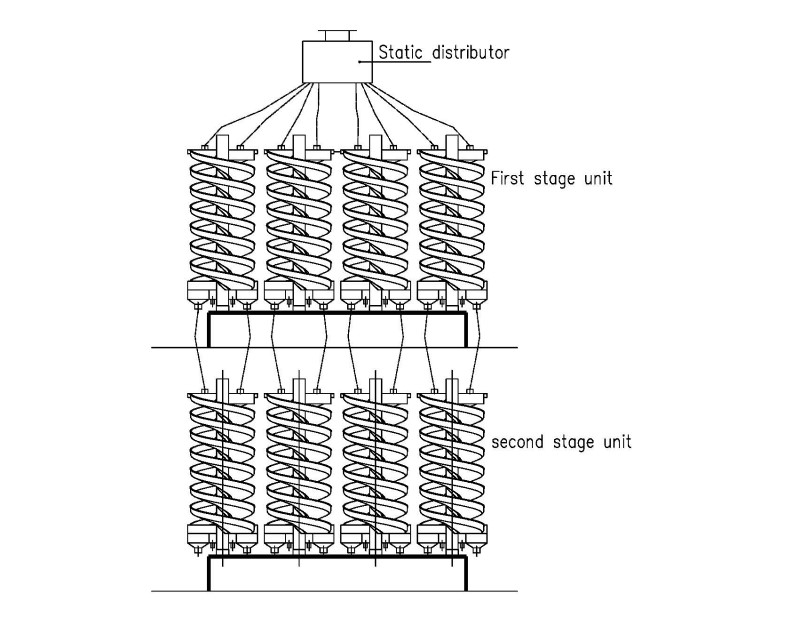

Based on years of experience, two-stage or three stage spiral concentrators are often arranged in silica sand production lines to achieve the best sorting effect. Below is the layout of two stage spial concentror in silica sand production line.

Benefits of spiral concentrator

Get an effective, low-cost device for the gravity beneficiation of ores. Sinonine spiral concentrators are used in most applications, particularly for concentrating low-grade ores. Manufactured from lightweight, corrosion and abrasion-resistant materials, our spirals require minimal maintenance and upkeep. Gives you an effective and low-cost solution for gravity separation Reduces maintenance with a durable design

Sinonine spiral concentrtor is made of integral modules, easy to install, and has the following advantages.

1.Wear resistant fiberglass material, long service life

2. Overall mold production, easy installation and replacement

3.Develop a composite curve based on the characteristics of silica sand material, with excellent separation effect.

4. Reduces maintenance with a durable design.

Specification of spiral concentrator

Model | Spiral diameter (mm) | Pitch (mm) | Start Qty | Turn Qty | Feeding size(mm) | Capacity(tph) | Dimension (mm) | Weight |

GL600-2 | 600 | 390 | 2 | 5 | 0.04-2.0 | 1.20-3.0 | Ø700x2550 | 72 |

GL600-3 | 600 | 390 | 3 | 5 | 0.04-2.0 | 2.0-4.5 | Ø700x2550 | 95 |

GL900-2 | 900 | 540 | 2 | 5 | 0.04-2.0 | 3.0-6.0 | Ø1030x3700 | 110 |

GL900-3 | 900 | 540 | 3 | 5 | 0.04-2.0 | 4.0-7.5 | Ø1030x3700 | 191 |

GL1200-2 | 1200 | 605 | 2 | 5 | 0.04-2.0 | 4.0-14 | Ø1250x4000 | 190 |

GL1200-3 | 1200 | 605 | 3 | 5 | 0.04-2.0 | 6.0-21 | Ø1250x4000 | 270 |

GL1200-4 | 1200 | 605 | 4 | 5 | 0.04-2.0 | 8.0-28 | Ø1250x4000 | 350 |

How to select a suitable spiral concentrator?

For maximum operating efficiency, feed density should remain constant, the particle-size distribution of the feed should be uniform, and fluctuations in feed volume should be minimized. Also, the spiral works best on a closely sized feed, though in select cases the unit has some tolerance for wide size ranges. In general, a coarse size limit would be about 2 mm and a fine limit of approximately 0.04mm. For best performance, feed should be relatively free of slimes as a high slime content may act like a heavy medium and decrease the effective differences in specific gravity between the minerals to be separated. If slime is in excess of 10% by weight, desliming prior to spiral concentration will almost certainly result in improved spiral performance.

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087