What is a attrition scrubber for sale?

Efficient attrition scrubbing removes unwanted contaminants, impurities, surface films, coatings, clays or slime, designed to achieve the strongest possible scrubbing to improve mineral values and create a more desired product, without damaging or degrading the recovered particles.

Applications for attrition scrubbers

Flotation – cleaning particle surfaces prior to flotation to increase selectivity.

Glass sand – removing iron oxide coating on silica sand by attrition and flotation to produce a low-iron glass sand.

Industrial sand – Scrubbing blasting sand and fracturing sand to disperse contaminating soft particles and other impurities, which are then removed by desliming. This process create a high purity silica sand, more crush resistant silica sand that will meet your customers’ specifications.

Ores and other minerals (e.g. phosphate) – freeing impurities so they can be removed with the help of a spiral classifier or hydrocyclone.

Dissolving solids – using the attrition machine to dissolve solids, reducing contact time by continuously exposing fresh surfaces to the solvent.

Working principle of attrition scrubber

The motor drives the main shaft to rotate through the belt pulley, causing negative pressure area on the blade. When the material passes through, it is stirred and rinsed thoroughly, and then pushed out by the blade and flows along the wall of the barrel. As the material is continuously sent in, the cleaned material is constantly discharged from the discharge port to finish the scrubbing work. The ore slurry enters into the chamber through the feeding pipe. Under the strong stirring action of the impeller, the negative pressure zone is generated in the blade. When the ore pulp passes through, it is stirred and rinsed thoroughly, and then pushed out by the blade to flow along the wall of the barrel. The ore pulp particles generate enormous momentum and cause violent friction and collision with each other.The impurity film wrapped on the surface of particles is easy to be separated from the ore surface by friction and impact. The adglutinate on the ore surface is soaked by water and then through the intense friction and collision between the ore particles, the adglutinate will also be loose and broken down, so as to achieve the separation of clay and ore particles. These film impurities and clay are broken down and flaked into the slurry, which can be separated after subsequent desliming.

Components of attrition scrubber

Tank

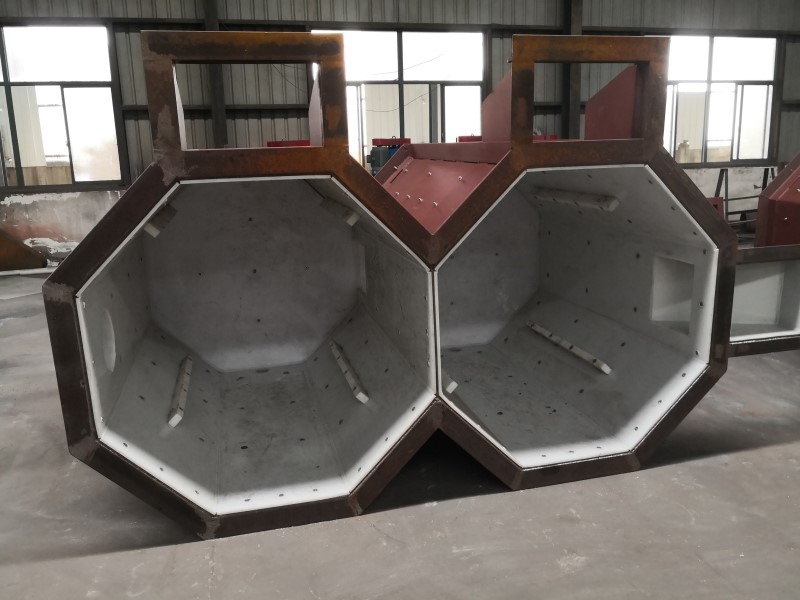

The cross section of the scrubber tank is an equilateral octagon and the tank is welded with optimized structural steel or stainless steel. The inner wall of the tank is coated with high-density polyethylene HTPE liner plates, and the gap of the liner plates is adglutinated and sealed, so that there is no leakage during prolonged use. High wear-resistant lining plate can be applied to the strong impact of various pulp, effectively protect the tank, and avoid iron pollution of pulp.

Drive

The operation of the scrubbing machine is driven by the motor to the impeller through the flexible triangle belt, which drives the impeller to run at high speed and generates strong scrubbing kinetic energy. The flexible driving has high driving efficiency, smooth operation and low noise, and avoids the possibility of impact damage to the driving system caused by the turbulent vibration of the slurry.

Drive shaft system

The drive shaft system is composed of precision cast outer cylinder and precision machined stainless steel long shaft. The bearing adopts high-strength rolling bearing, and the bearing chamber is precision sealed. The shafting system is finely assembled and strictly checked for dynamic and static balance. It has comprehensive mechanical properties such as high strength impact resistance and long life.

The impeller

The impeller is arranged with two or three layers up and down to meet the needs of different concentrations of slurry. When the impeller is running, strong scrubbing kinetic energy is generated inside the barrel, so that the slurry can be fully rolling and friction, and the ideal scrubbing effect can be achieved. The impeller is made of wear-resistant polyurethane and cast-in-block, easy to disassemble and maintain. The polyurethane blades of impeller are thick and wear-resistant, light weight and greatly reduced energy consumption.

Ultrasonic device

The attrition scrubber can be customized with ultrasonic device under the client request, the ultrasonic wave is evenly arranged on the barrel wall, the ultrasonic wave is generated and applied to the being scrubbed slurry. Adding proper amount of oxalic acid, a more ideal effect of iron reduction and impurity removal can be achieved.

High temperature and corrosion resistant treatment for attrition scrubber

If the attrition scrubber needs to deal with high temperature corrosive slurry, the attrition can be configured with properties of high temperature and corrosion resistance, and non-metallic wear-resistant brick can be installed as the inner wall, and the impeller can be treated with high temperature and corrosion resistance.

Features and technology advantages of attrition scrubber

-Small power consumption, strong intensity of scrubbing and stirring, favorable effectiveness.

-The impeller is above the slurry settling area, easy to start and low power to start.

-Low circumferential speed of the impeller and long service life.

-Simple equipment structure, large effective volume and small floor space.

-Diversified customization to meet your different needs

Sinonine offer a variety of attrition cell machine arrangements, based on your specific application. For example, add ultrasonic equipment ,make a scrubber with corrosion resistance.

Specification of attrition scrubber

Model | Single volume (m³) | Cell quantity | Input size(mm) | Pulp density | Power (kw) | Dimension (L×W×H) (mm) | Weight |

AS0.5-2 | 0.5 | 2 | 0-5 | <70% | 7.5x2 | 1340×920×1350 | 1100 |

AS1-2 | 1 | 2 | 0-5 | <70% | 15x2 | 2774x1510x2057 | 2400 |

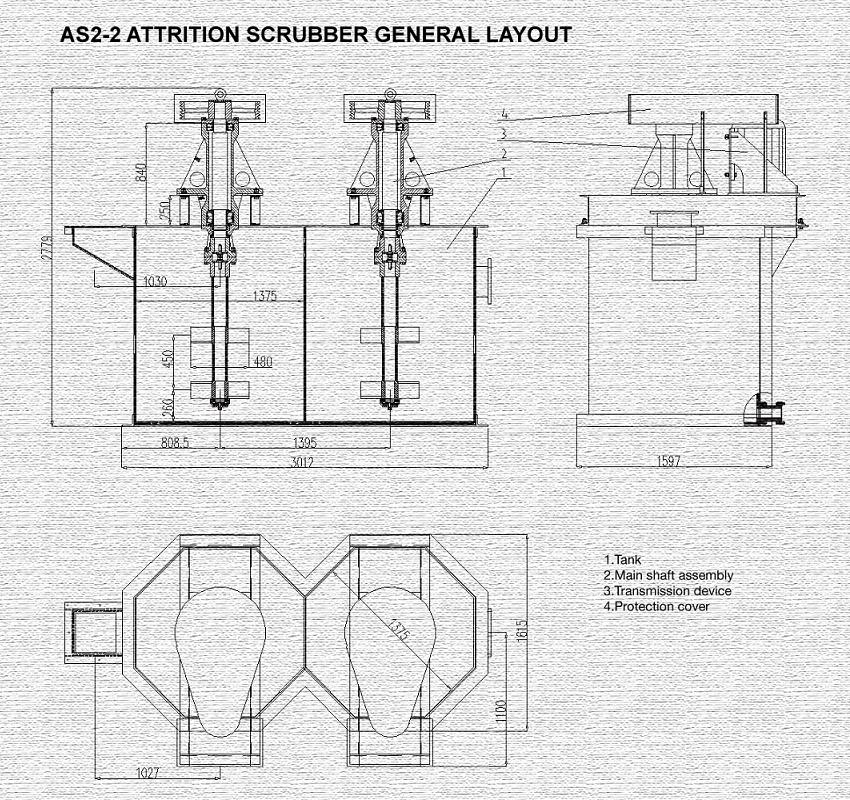

AS2-2 | 2 | 2 | 0-5 | <70% | 30x2 | 3012x1597x2997 | 4800 |

AS4-2 | 4 | 2 | 0-5 | <70% | 75x2 | 3536x1852x5395 | 9600 |

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087