This blog introduces the production and purification technology of high-purity quartz sand and high-purity ultra-fine quartz powder, so that their products can be applied in the fields of chip, monocrystalline silicon, optical fiber cable, military industry, fine chemical industry and microelectronics.

|  |

Problems of traditional way of processing high purity quartz sand and high purity quartz powder

The traditional production and purification processes of quartz sand and quartz powder generally adopt the following two processes.

1.The raw ore is roughly separated, crushed, roasted, water crushed, dry or wet ground, and iron removed, and finally quartz sand of 10 to 325 meshes is produced.

2.Quartz sand and quartz powder of 10 to 800 mesh were prepared from quartz raw ore by roughing, ordinary water washing, dry grinding or wet grinding, mechanical iron removal, industrial sulfuric acid treatment, mechanical surface modification and drying.

The above production and purification process is simple, the inclusion impurities and surface impurities of quartz and the contamination impurities of production process can not be effectively removed, and the purity of quartz sand and quartz powder is not high (the purity of quartz sand is 99.5% to 99.6%, the purity of quartz powder is 99.1% to 99.2%), and the fineness of quartz powder is only 800 meshes. In glass production, it is easy to foam and even produce water marks. In the application of casting filler, the purity of quartz powder is low. It is also easy to foam and affects the quality of products. It can not be applied in the fields of chip, monocrystalline silicon, optical fiber cable, military industry, fine chemical industry and microelectronics.

Processing technology of high purity silica sand

After long-term research, Sinonine has obtained an efficient production method of high purity quartz sand and quartz powder. The production process solves the problem that quartz sand and quartz powder are easy to produce water marks and foams in production and application because of their low purity, which seriously affects the quality of products. At the same time, it expands the application fields of quartz sand and quartz powder, and meets the production requirements of high-tech products such as chips, monocrystalline silicon, optical fiber cable, military industry, fine chemical industry and microelectronics.

|  |

The corresponding processing technology of high purity quartz powder is as follows:

In order to achieve the above objectives, the following technological processes are used for the preparation and purification of quartz sand: quartz raw ore, roughing, crushing, primary separation, roasting, water crushing, oxalic acid or citric acid leaching, dry grinding or wet grinding, gradient magnetic separation, classification, combination process washing, flotation, deionized water washing, special drying, vacuum packaging. Following is the introduction of each process.

Roughing: removing the coarse impurities and obvious impurities from all kinds of quartz raw ores;

Crushing: The quartz raw ore is crushed to 0.5-8mm particle size by professional crusher.

Primary separation: refers to manual selection to remove impurities from quartz raw ore particles.

Roasting: refers to the use of professional roasting kiln, quartz raw ore granules are placed in the furnace to roast, at 300 to 1200 degrees C for 2-8 hours;

|  |

Dry grinding or wet grinding: refers to the use of special quartz rod mill or ball mill to grind quartz sand of 10-325 mesh under the condition of no water or water.

High gradient magnetic separation: refers to the removal of iron in quartz sand and contaminated iron in production process by using magnetic drum separator with magnetic intensity of 50-15 000 Gauss and high gradient magnetic separator.

|  |

Classification: Quartz sand with 10 to 325 meshes is divided into 10 to 50 meshes, 60 to 100 meshes, 110 to 150 meshes, 160 to 200 meshes, 210 to 250 meshes, 260 to 300 meshes and 310 to 325 meshes according to the standard by hydraulic classifier.

Combined process washing: quartz sand with different contents is placed on different layers of temperature-controlled reactor, adding oxalic acid or citric acid, and a small amount of other auxiliary medicines, reacting for 3-8 hours at constant temperature of 60-90 degrees, in order to remove harmful trace metal and non-metallic impurities in quartz sand.

Flotation: Removal of impurities using flotation machine with chemical reagents and specific gravity less than water after washing by OECD process;

Deionized washing: In the stationary workshop, the residual chemical agents and impurities on the surface of quartz sand after flotation are further removed by attrition scrubber and spiral sand washing machine to make the PH value up to the standard.

Special drying: Deionized and dehydrated quartz sand is dried in a silica sand dryer in a stationary workshop with special equipment to produce 10-325 meshes of high purity quartz sand of different grades, i.e. 99.9% to 99.995% purity.

Vacuum packing: In the stationary workshop, 10-325 meshes of high purity quartz sand with different grades are vacuum packaged separately to avoid air pollution.

Processing technology of high purity quartz powder

The corresponding processing technology of high purity quartz powder is as follows:

The flotation quartz sand ultra-fine grinding (dry or wet grinding), combined process washing ,high-level magnetic separation ,electrostatic separation, deionized water washing, classification ,special drying and vacuum packaging.

|  |

Ultra-fine grinding (dry grinding or wet grinding): refers to the grinding of quartz sand to 325-4000 mesh ultra-fine quartz powder without water or water.

Classification: Hydraulic classifier is used to classify 325-4000 mesh ultrafine quartz powder according to standard interval, such as 325-400 mesh, 400-500 mesh, and so on.

Combining process washing: Ultrafine quartz powder of different grades is placed on different layers of temperature-controlled reactor, adding oxalic acid or citric acid, at constant temperature from 70 to 100 degrees, reacting for 2-8 hours, removing harmful trace metals and non-metallic impurities in ultra-fine quartz powder.

High gradient magnetic separation (HGMS): refers to the removal of trace iron from ultrafine quartz powder by magnetic separation equipment with magnetic intensity of 50-15 000 gauss.

Deionized washing: In the stationary workshop, the harmful trace impurities on the surface of chemical agents and quartz powder washed by the combined process are removed.

Special drying: The ultra-fine quartz powder washed by deionized water is put into the dryer in the static workshop and dried to produce 325-4000 mesh high purity ultra-fine quartz powder of different grades. Its purity is 99.9% to 99.9996%, and its water content is 0.003% to 0.01%.

Vacuum packing: Vacuum packing of ultrafine quartz powder of various grades to avoid air pollution.

Special equipment and special drying equipment for process washing are all on the metal surface contacted with quartz sand or quartz powder by existing temperature-controlled reactor and dryer. High silicon material or ceramic material or insulating grease material is used to avoid contamination of quartz sand or quartz powder by equipment.

The special equipment for dry or wet grinding is also made of high silicon material for the grinding parts of existing dry or wet grinders, so as to avoid the pollution of quartz sand or quartz powder by the grinding parts.

The above high purity quartz sand and quartz powder production process can achieve the following results:

1.In the process of production and purification, special equipment for lining high silicon material is adopted, which avoids the contamination of quartz sand or quartz powder by equipment, thus ensuring the improvement of purity in hardware.

2.High gradient magnetic separation uses high frequency, high voltage and high gradient electric field instead of electrostatic field. It uses the effect of the dielectric constant of minerals changing with the frequency of electric field to improve the resolution of mineral processing, so that the iron in quartz sand or quartz powder can be removed and the high purity can be guaranteed from the process.

3.Ultra-fine grinding is a steam flow super-fine grinding with lining high silicon material, which makes the fineness of quartz powder meet the application requirements of related high-tech products.

4.The combined process wash breaks through the traditional process of sulfuric acid or hydrochloric acid production, uses oxalic acid or citric acid, saves materials, reduces costs, avoids pollution, meets the national environmental protection requirements, improves the mineral processing rate and precision, and has a reasonable formula.

5.The high purity quartz sand produced by this process does not foam the glass and chip, the optical fiber cable will not break, and the glass has no water mark. Its application in military industry can meet the requirements of high hardness and purity, and the application field has been expanded.

What are the applications of High purity quartz sand(HPQ)?

The high-purity quartz sand with a SiO2 content of up to 99.999%, meeting the needs of high-end manufacturing industries, mainly reflected in the following aspects.

-Quartz crucible sand

-Quartz tube sand

-Quartz ingot sand

-Electronic sand

-Quartz glass

|  |

|  |

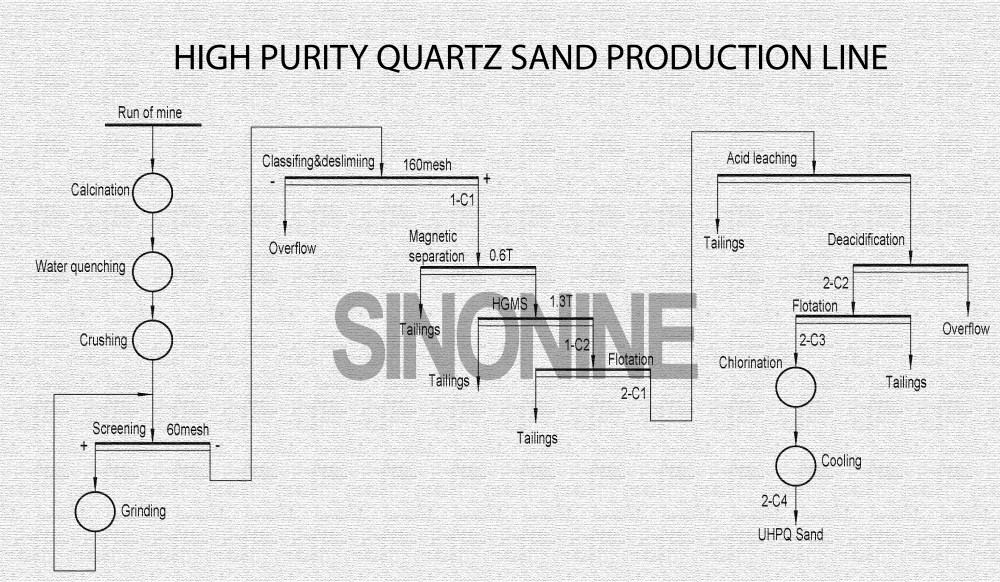

High purity quartz technical process flowchart

Remarks: The whole process can also be changed according to the situation, without affecting product quality. For more details, please contact Sinonine. WhatsApp:+86-18118821087

The flotation method provided by Sinonine can effectively remove feldspar in quartz sand, which is widely used in quartz sand washing plant and has achieved good results.

Sinonine high purity silica sand washing plant can work 7x24 hours to Meet the needs of customers in large production. www.9silica.com, +8618118821087

Raw sand go into silica sand washing plant to become high purity sand.

High-purity quartz powder has excellent optical, thermal, chemical stability and radiation resistance, so it has a wide range of applications in electronic industry, optical communications, military and other fields. With the development of electronic industry, optical communication, laser, optics a

sand washing plant for high purity sand

After drying by fluidized bed dryer system, the moisture content of silica sand can be less than 0.5%, and the moisture distribution is very uniform.

Most of the hydraulic graders in sand washing plants adopt the automatic control system, which has achieved good results.

The processing technology of high purity quartz sand washing plant usually includes complex processes such as calcination, water quenching, classification, magnetic separation, flotation, acid leaching, cleaning and chlorination roasting.

Thank you for your interests in Sinonine, Please feel free to submit your inquiry information to us, our expert will contact with you as soon as possible.